3D Printing

StereoLithography (SLA) & Selective Laser Sintering (SLS)

Accurate professional 3D printed parts directly from 3D CAD data in a matter of hours without drawings, tooling, or machining.

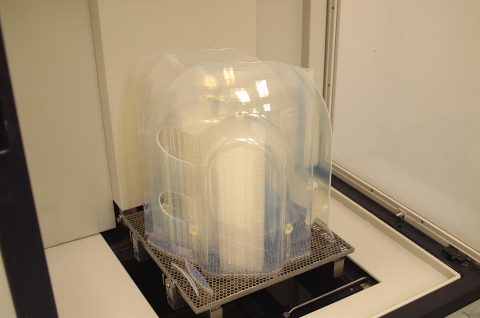

StereoLithography (SLA)

protoCAD typically uses Somos® ProtoGen 18120 to produce ABS-like accurate parts that are ideal for general purpose applications. The parts are chemical resistance and ideal for the medical, electronic, aerospace and automotive markets. They make accurate RTV patterns, durable concept models. They are highly accurate and humidity & temperature resistant.

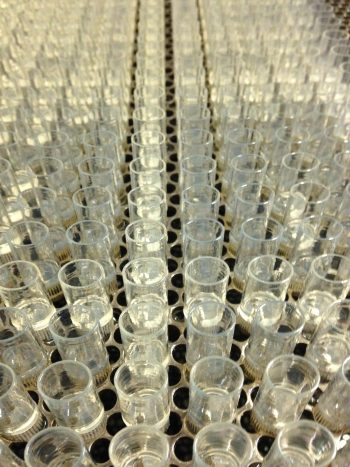

Selective Laser Sintering (SLS)

Nylon 12 is a general purpose, versatile, and biocompatible material with high detail and great dimensional accuracy. It is ideal for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

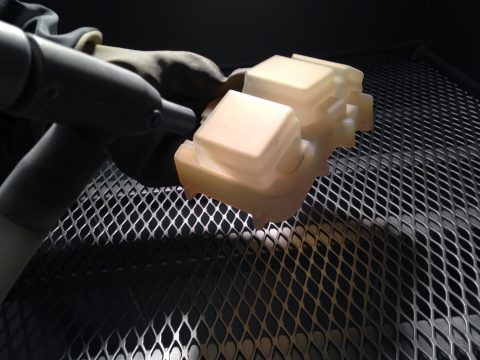

Threads

SLS: protoCAD taps threads, installs inserts or installs Helicoils. Large threads can be 3D printed

SLA: protoCAD installs Helicoils, adheres inserts, and taps threads. Large threads can be 3D printed.

Rapid Delivery

SLS & SLA: Most parts are delivered in 2-3 business days depending on the size and volume of the part(s).

Size

SLS: Parts up to 6.5″X6.5″X12.5″.

SLA: Up to 20″X20″X24″ in a single build. Parts as large as 4’X3’X1′ have been printed by breaking the part into multiple pieces then assembling them after they have been printed.

Quantity

SLS & SLA: Quantities range from a single part that might be used for a design evaluation to thousands of parts that are used as production parts.

Accuracy

We work with our customers to ensure critical tolerances are achieved even if that requires a secondary process.

SLS: Generally within +/-.010″ with an additional +/-.001 in/in.

SLA: Very accurate and are generally within +/-.005″ with an additional +/-.001 in/in.

Finish

protoCAD will work with the customer to provide any specialty finish they may desire.

SLS: Bead Blast Finish

SLA: Generally a bead blast finish. The parts can also be provided without a finish, or a polished finished.

Armor Coating

3D printed parts and Urethane Castings can be strengthened and hardened or electronically shielded using a thin coating of copper and nickel to form armor coating. Armor coating can be applied to entire part or selected part surfaces.

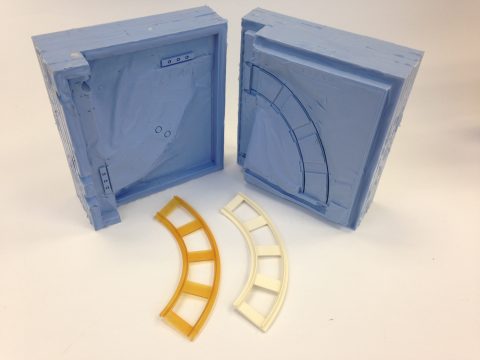

Master Patterns

3D printed StereoLithography parts are ideal for Urethane Casting master patterns as they are very accurate and have a beautiful surface finish.

Colors/Transparency

SLS: Naturally Black – Can be painted or dyed black.

SLA: Naturally Light Amber. Can be painted or dyed. Polished parts are transparent with an amber tint.

Process

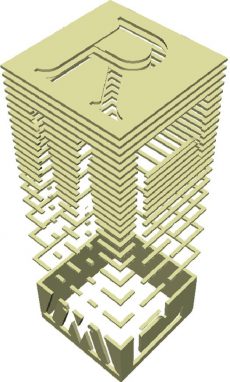

SLS: A laser traces a cross-section onto nylon powder fusing the nylon together. Additional nylon powder is placed on the surface. The laser then fuses the next cross-section. This process is repeated until complete. No supports are required for this process.

SLA: A laser traces a cross-section onto the surface of a bath of photopolymer solidifying the cross-section. The part is lowered into the bath and resin is swept onto the surface. The laser then solidifies the next cross-section. This process is repeated until complete.

3D Printing Quick Quote

3D Printing Quick Quote