Urethane Casting

A Step Above 3D Printing!

protoCAD manufactures vacuum cast urethane rigid and flexible parts. Vacuum cast urethane parts are production quality, economical, and can be in your hands in a matter of days.

Urethane Materials

We cast a wide range of high performance rigid and flexible materials. Urethanes are tough and significantly stronger than 3D printed parts.

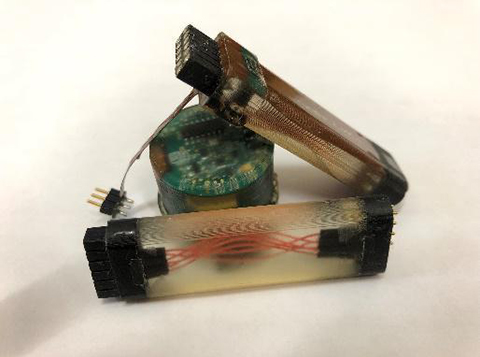

Potting Electronics

Epoxies and Urethanes are used to encapsulate circuit boards and components for protection from such things as shock and vibration. The potting material also protects them from moisture, dust and other contaminants.

Silicone Castings

Silicone parts have high tear and tensile strength, good abrasion resistance, and excellent dimensional stability. Durometers range from 10A to 80A. Food grade silicones are available.

Colors/Transparency

The urethane castings can be pigmented with a wide range of colors. Color matching is available. Water Clear Urethanes are also available.

Insert/Threads

Threaded inserts are cast in place. Helicoils are generally used when there is not enough material for an insert. The helicoils are installed after casting. Threads can also be cast or machined.

Size

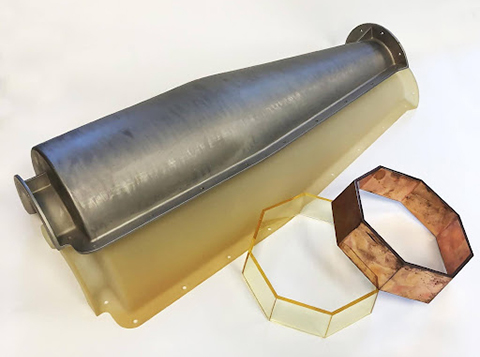

protoCAD has vacuum cast urethane parts approaching 4′ by 3′ by 1′ and weighing more than 10 pounds.

Rapid Delivery

Urethane casting is a very fast manufacturing method. With a pattern in hand, the mold is usually made in two days. Urethane parts are then cast starting on the third day. We work closely with each customer to meet their delivery requirements.

Quantity

The quantity can range from 1 to 100s. To cast high quantities we make muti-cavity molds and/or multiple molds.

Accuracy

Urethane castings (excluding those with thick cross-sections) are not greatly affected by shrinkage. Urethane castings are accurate and we work with the customers to ensure their critical tolerances are achieved.

Finish

The urethane casting finish will match that of the master pattern. The finish is usually matte but can be polished and/or textured.

Durometer

Durometers for Urethanes range from 10A to 90D. Hardness can also be increased with the addition of structural fillers such as glass or carbon.

Composite

A variety of fillers can be added to flexible and rigid urethane castings to customize their properties.

Co-Molded

Other items may be co-molded with urethane castings. We have co-molded: electrical wires, vacuum tubes, magnets, metal plates, inserts, electronic connectors, lenses, metal bands, rigid castings inside flexible castings, electronic boards, studs, & acrylic windows.

Armor Coating

Urethane Castings and 3D printed parts can be strengthened and hardened or electronically shielded using a thin coating of copper and nickel to form armor coating. Armor coating can be applied to entire part or selected part surfaces.

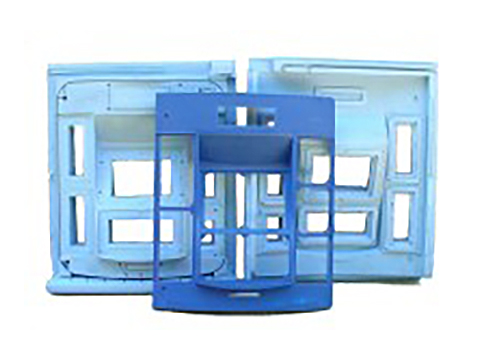

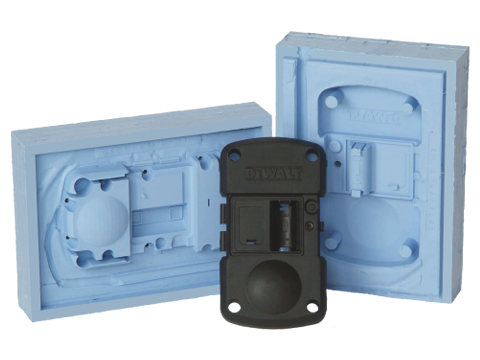

Process

A pattern is staged and encapsulated in a silicone rubber. After the rubber cures, the pattern is removed leaving it’s impression in the silicone rubber mold. The mold is placed under vacuum and is filled with a two-part urethane. The urethane hardens under pressure and is removed, detailed and verified to meet customer requirements.

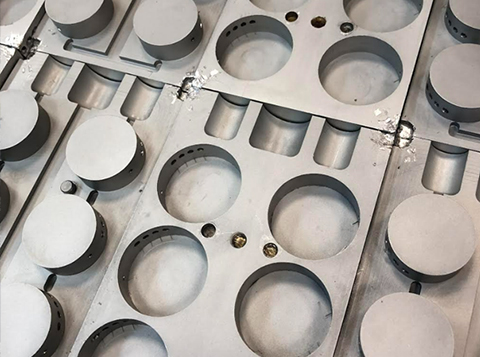

Very Accurate Parts

protoCAD cast parts in machined molds to meet tight tolerance requirements.

Urethane Casting Quick Quote

Urethane Casting Quick Quote